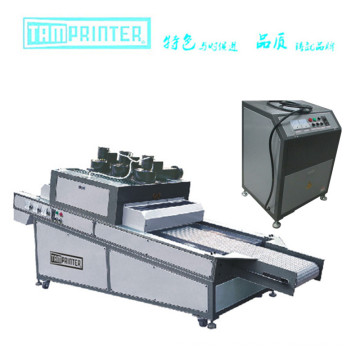

TM-UV-D Offset UV Drying Machine for Offset Silk Screen Printer

Basic Info

Model No.: TM-UV-D

Product Description

Model NO.: TM-UV-D Operational Method: Continuous Drying Medium: Air Heating Mode: Transmission Power: 380V 3phase Insert Width(mm): 620 Distance From Belt to Ground(mm): 450 Electric Control Box Size(Cm): 60*97*99 Offset Print Speed(PCS/H): 6000 Trademark: Tamprinter Specification: CE; ISO9001-2000 HS Code: 8443192290 Structure: Oven Operation Pressure: Atmospheric Dryer Appearance of Dried Sample: Pastes Movement Way: Fixed UV Lamp: 2PCS*9.6kw Insert Depth(mm): 900 Weight (Kg): 700 Body Size (Cm): 400*135*145 Sheet Size(mm): 520X360 Transport Package: Plywood or as Required. Origin: Guangdong, China TM-UV-D Offset UV Drying Machine For Offset Silk Screen Printer

Technical Parameters

Application

This machine is offset Post-press drying equipment, Heidelberg, Man Roland and Komori printer and so on or a printer supporting.

Quality, special design, and advantages of main parts:

(1)Adopt imported UV light tube, and have long useful time, and more stable wavelength.

(2)Adopting glisten film made in Germany and installing specially designed focused lampshade can promote UV energy effectively, and make the solidifying ability of the machine stronger.

(3)Exclusive design of ultralow temperature of irradiated area makes printing heat sensitive paper, film, and 0.05mm thin film not become deformed, and reprint exact.

(4)The machine adopts specially designed heat removal system, drops off UV heat, and also does not lower UV energy, makes materials stable, does not float, stop, trap in the light chest

(5)Light source is divided into bright light, middle light, and dim light, unattached switch allocating energy-saving leakage transfer motor produced by the factory make the energy of UV light exert to the highest-level, meanwhile save electric power changes.

(6)The machine is equipped with transformer and over temperature protection device of lighting tube.

(7)Divided design (fuselage is separated from mainframe) is easy to operate, and can be pushed.

(8)The machine prints with Printing Machine at the same time: discharge velocity of rapid solidifying is 70m per minute(mph 6000 pieces of paper).

(9)The machine has many types, and can be made to order according to the requirements of customers, the solidifying speed is 5-70m/min and can be adjusted.

Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about UV Drying Machine、Offset UV Drying Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about UV Drying Machine、Offset UV Drying Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Technical Parameters

| Type | TM-UV-F5 |

| Power | 380v 3phase |

| UV Lamp | 2pcs*9.6kw |

| Insert width(mm) | 620 |

| Insert depth(mm) | 900 |

| Distance from belt to ground(mm) | 450 |

| Weight (Kg) | 700 |

| Electric control box size(cm) | 60*97*99 |

| Body size (cm) | 400*135*145 |

| offset print speed(pcs/h) | 6000 |

| Sheet size(mm) | 520x360 |

Application

This machine is offset Post-press drying equipment, Heidelberg, Man Roland and Komori printer and so on or a printer supporting.

Quality, special design, and advantages of main parts:

(1)Adopt imported UV light tube, and have long useful time, and more stable wavelength.

(2)Adopting glisten film made in Germany and installing specially designed focused lampshade can promote UV energy effectively, and make the solidifying ability of the machine stronger.

(3)Exclusive design of ultralow temperature of irradiated area makes printing heat sensitive paper, film, and 0.05mm thin film not become deformed, and reprint exact.

(4)The machine adopts specially designed heat removal system, drops off UV heat, and also does not lower UV energy, makes materials stable, does not float, stop, trap in the light chest

(5)Light source is divided into bright light, middle light, and dim light, unattached switch allocating energy-saving leakage transfer motor produced by the factory make the energy of UV light exert to the highest-level, meanwhile save electric power changes.

(6)The machine is equipped with transformer and over temperature protection device of lighting tube.

(7)Divided design (fuselage is separated from mainframe) is easy to operate, and can be pushed.

(8)The machine prints with Printing Machine at the same time: discharge velocity of rapid solidifying is 70m per minute(mph 6000 pieces of paper).

(9)The machine has many types, and can be made to order according to the requirements of customers, the solidifying speed is 5-70m/min and can be adjusted.

Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about UV Drying Machine、Offset UV Drying Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about UV Drying Machine、Offset UV Drying Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : UV Curing Machine > Other UV Curing Machine

Premium Related Products

Other Products

Hot Products

TM-AG900 High Quality Automatic Glitter Powder Coating MachineTam-F70A Air-Gas Burner Flame Treatment MachineTM-LED-150 Small Light Curing MachineTmg-1200h Automatic Screen Printing Squeegee Sharpener Squeegee Grinding MachineTM-IR1200m 300 Degree Celsius Dryer Glass Drying Machine Tunnel OvenTM-R6 2.14*2.14*1.15 M Cheap Manual Rotary 6-Color T-Shirt Screen Printing Machine with Flash DryerTM-C2-P High Quality Label Two Color Pad Printing MachineTM-S61 Ink Cup 6 Color Servo Pad Printer with ShuttleTM-F3 High Quality Cylinder Flame Treatment MachineUSB Mini Electric Pad Printer (TDY-300)High Speed One Color Tabletop Pad Printing Machine (TM-MINI)Tam-170-C Fabric Handbag Leather Embossing Manual A4 Hot Stamping MachinePneumatic Bottle Screen Printing Machine ManufacturerTM-R6 Manual 6-Color Texitile Screen Printer for T Shirt with SqueegeeTM-UV750 Ce UV Curing Machine for PlasticCe Automatic Large Format Oblique Arm Flat Screen Printing Machine